Table of Contents

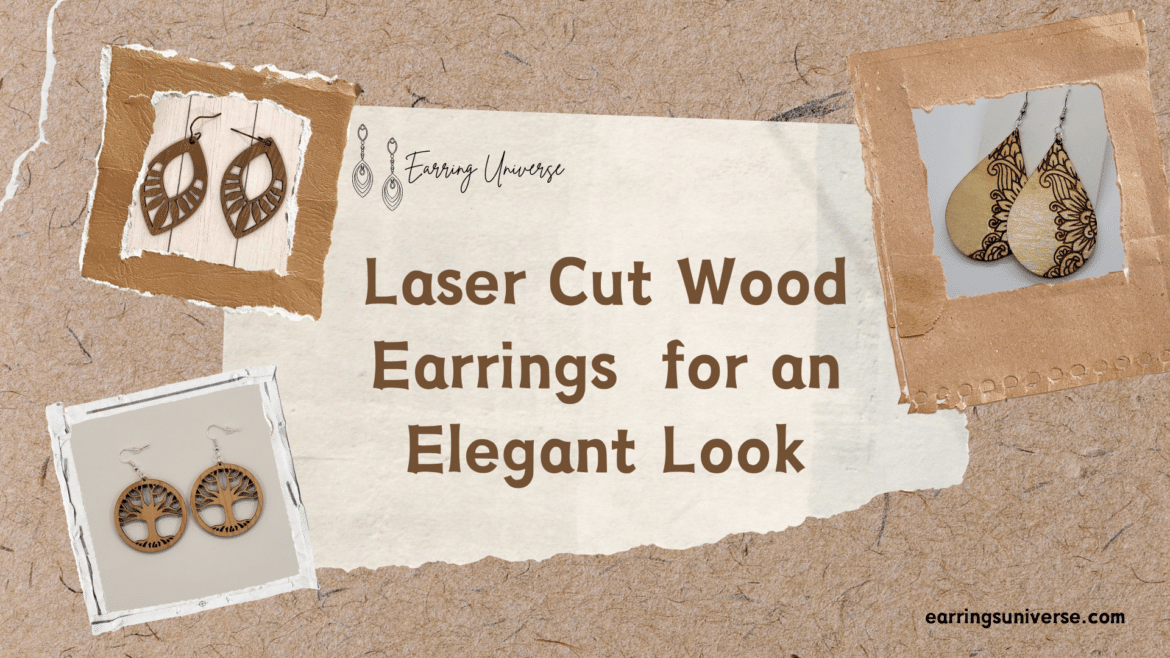

Running out of jewelry? Why not craft your very own laser cut wood earrings this time? Lightweight, attractive laser-cut wood earrings lend beauty to any ensemble. Custom wooden earrings are now easy to make thanks to laser cutting and engraving. By selecting the proper wood thickness and following innovative design suggestions, you may create distinctive, eye-catching items that express your personality. Let us everything about these wood cut earrings.

Why Choose Laser Cut Wood Earrings?

First and foremost, you need to know why these crafty laser cut wood earrings are worth a try. DIYers and jewellery lovers enjoy laser cut wood earrings for their versatility, personalization, and creativity. Whether you’re a beginner or an expert, these earrings provide endless design possibilities. You can make lightweight, eco-friendly earrings that match your style with the best wood thickness.

- Design Freedom: Use design files to create unique, laser engraved earring patterns.

- Material Options: Experiment with veneer sheets or various wood types for distinct aesthetics.

- Beginner-Friendly: Learn how to make laser cut wood earrings with a CO2 laser cutter.

- Lightweight and Eco-Friendly: Achieve stylish yet sustainable designs with wood for laser engraving.

Types of Wood for Laser Engraving

When selecting wood for laser engraving, consider these options;

- Veneer Sheets: Great for beginners; they’re easy to cut and engrave.

- Plywood: Affordable and durable, ideal for layered designs.

- Solid Wood: Offers a natural look with unique grain patterns.

- Bamboo: Sustainable and lightweight, perfect for eco-friendly designs.

Always test your laser cutter settings on a sample piece to achieve the desired results.

Tools and Materials Needed

To make wooden earrings, you’ll need;

- Laser Cutter: A CO2 laser cutter is ideal for precision and efficiency.

- Design Files: Use software like Adobe Illustrator or Inkscape to create your earring designs.

- Wood Sheets: Choose your preferred type and thickness.

- Earring Hooks and Jump Rings: Essential for assembling your earrings.

- Sandpaper: For smoothing edges after cutting.

- Optional: Paint or varnish for added color and protection.

How to Make Laser Cut Wood Earrings for Beginners

Follow these steps to create your first pair of laser cut earrings;

- Design Your Earrings: Use design software to create patterns. Save the file in a format compatible with your laser cutter.

- Prepare the Wood: Choose a wood sheet of the desired thickness and ensure it’s clean and smooth.

- Set Up Your Laser Cutter: Adjust the settings based on your wood type and thickness.

- Cut and Engrave: Load your design file into the laser cutter. Perform a test cut to ensure precision.

- Assemble the Earrings: Smooth the edges with sandpaper, attach earring hooks, and finish with paint or varnish if desired.

Tips for Stunning Earring Designs

Here is a look at some of the tips to keep in mind to make the perfect wooden earrings.

- Experiment with Layers: Combine different wood types for a multi-dimensional look.

- Incorporate Engraving: Add intricate patterns or text to personalize your earrings.

- Use Color: Paint or stain the wood for vibrant designs.

In a Nutshell

Summing up, laser cut wood earrings let you create unique items using the best thickness wood and laser engraving techniques. CO2 lasers can cut or engrave veneer sheets, earring hooks, and design files for beginners.

In conclusion, DIY wooden earrings allow for customization, cost savings, and unlimited creativity. Try this rewarding pastime and produce beautiful earrings today!

CREATE YOUR OWN STYLE!